Flawless quality is not an aspiration; it’s an expectation.

The world’s most prestigious companies know Caran Precision because of our Quality. This doesn’t happen on its own. Quality comes from quality operations, processes, technologies, and people. To get a quality product out, we must put quality in at every step. Supported by a well-established Quality Planning Process, Caran Precision will understand your requirements and meet them from the beginning.

Caran Precision is certified and compliant with ISO standards (ISO 9001:2015), IATF16949:2016, AS9100D and meets the requirements of Nuclear 10CFR50, Appendix B, NQA-1 and 10CFR Part 21. From prototype to final product, Caran Precision is driven by an unwavering commitment to quality. We utilize Advanced Product Quality Planning (APQP), Control plans, PPAP, PFMEA’s, Safe launch inspection, Capability – Product validation studies, and other quality tools to meet every requirement right the first time and every time. As part of our relentless drive to reach a zero defect level, we also employ highly disciplined and data-driven Six Sigma methodologies.

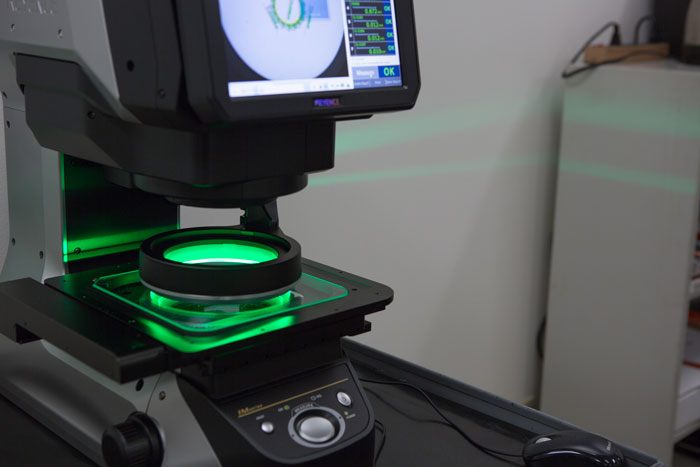

Caran Precision has the latest automated precision measurement equipment for highly accurate dimensional analysis. Systems utilizing optical and CMM capabilities allow us to maintain consistent measurement accuracy. Continual inspection and gauging during all stages of the processes make certain that we meet or exceed the quality criteria for our products. Real-time Statistical Process Control with automated input is also used for critical component characteristics to maintain process capability and ensure consistent conformance to our customers’ specifications. Our in-house metallurgical laboratory support our process and product quality.