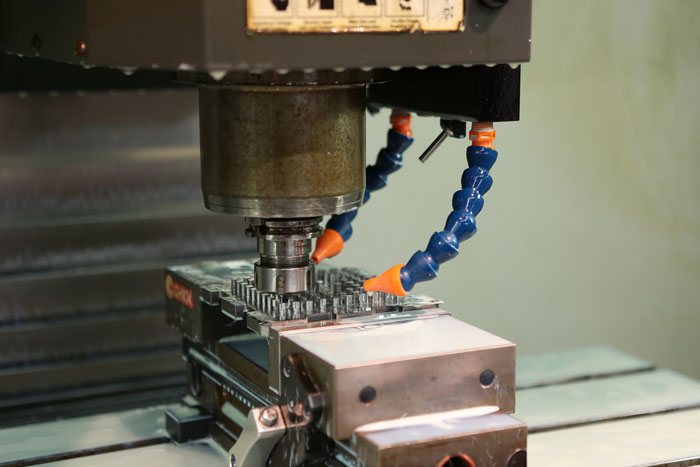

Since our inception in 1964, we have witnessed dramatic changes in manufacturing technologies. Caran Precision has embraced those technological advancements to better serve our customers. Caran is vertically integrated in order to retain control over our manufacturing and secondary processes, which include dedicated manufacturing lines, cellular manufacturing, stamping, welding, assembly, machining, cleaning, deburring and heat treating. This integration allows for steady production processes to reach our goal of 100% On-Time delivery and Zero Defects. We are able to serve a huge span of industries, including automotive, aerospace and nuclear because of our “One-Stop” approach.